Badeecada Guud

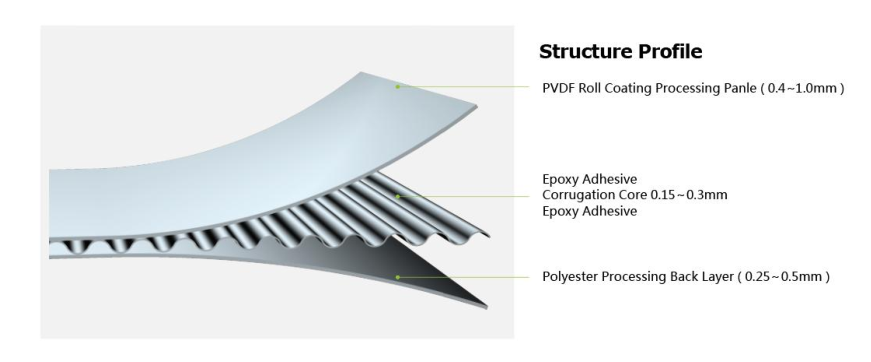

Aluminium Corrugated Composite Panel waxa kale oo loo yaqaan aluminium corrugated guddi ka kooban, isticmaalaya AL3003H16-H18 aluminium aluminium walxaha, oo wejiga aluminium dhumucdiisuna waxay tahay 0.4-1.Omm, dhumucdiisuna waxay hoose 0.25-0.5mm, dhumucdiisuna waxay 0.15-0.3mm.Waxaa la soo saaray on horumarsan qalabka wax soo saarka si toos ah by walax soo saarka ee nidaamka qaboojiyaha. laynka, addoo isticmaalaya heerkulbeeg-dhismeed dual qaab-dhismeed ku dheggan wajiga iyo aluminiumka hoose ee qaabka arc, kordhiya xoogga xabagta, haysashada biraha adhesion aad u fiican. Hubi in awoodda koollada ay deggan tahay oo ay la wadaagaan nolol isku mid ah dhismaha.

Aluminium Corrugated Panel Panel-ka-waqtiga labaad ee farsamaynta:

> goyn

- Goynta goynta isku dhafan ee aluminiumku waa inay isticmaashaa mishiinka goynta gaarka ah, gooyay si waafaqsan cabbirka loo qaabeeyey ka dib markii lagu hagaajiyo meel siman.

- Cidhifka goynta waa inuu ahaadaa mid aad u fiican oo nadiif ah.

> Goynta

Habka muhiimka ah ee farsamaynta guddida isku dhafan ee aluminiumku waa

jeexjeexin 0.15-0.2mm ee aluminiumka hoose

aluminiumka hoose iyo xudunta jiingado wada jir ah una gal 91 xagal darajo.

1) Mishiinka wax lagu farsameeyaa waxa uu la mid yahay sawirka dhexe ee hoose. Isticmaal miinshaarta R5.5 iyo xagasha 91

shahaado.

2) jeex-jeexid ballaaran, isticmaal miinshaarta jeexjeexa ee sawirka iyo dhaqdhaqaaqa makaanikada

qalabka si loo hagaajiyo waxtarka wax soo saarka.

Goynta: sida ku cad naqshadaynta sawirka, hababka cidhifyada soo celinta waa in la gooyaa

sida ku cad sawirka bidix.

> qaabaynta

- U qaabaynta ka dib jeexjeexa, ku hagaaji badeecada meel siman oo gaar ah, u leexi xagal 90 darajo oo leh xajin foorarsi ah sida waafaqsan jaantuska naqshadeynta.

-Qaybta koonaha ee foorarsiga waa inay si toos ah u ilaalisaa (la ogow in si looga hortago in daahan jaban qaybta geeska, shaqada waa in lagu shaqeeyaa in ka badan 10 ° C.

- Dhererka foorarsiga ugu yaraan 20 mm ka sarreeya cidhifka naqshadeynta, qaybtan xagasha leh jel silica waxay gaari kartaa saameyn ka wanaagsan biyuhu iyo waxyaabo kale.)

> Wareegto Wareegto

- Shahaadooyinka farsamaynta badeecada, isticmaal saxanka caadiga ah ee saddexda rullalula.

-Badeecadaha arc-ka-shaqaynta waxay ku hayaan 100 mm inay u bilowdaan halbeeg ahaan.

- Marka la rogrogo, ma joogsan karo.

- Waa in fiiro gaar ah u yeelo jihada, rog roga giraangiraha iyo guddiga xudunta u ah jihada toosan.

> Ogeysiis ku saabsan Grooving

A) Laab laabashada iyo goynta profile iswaafaqayn

-Ka saarida 0.15-o.2mm xaashida dibadda inta lagu jiro jeexjeexa.

-Xeejinta xajintu si qoto dheer uma gelinayso flange-ga.

- Kordhinta waxay u baahan tahay hawlwadeen khibrad leh, waxay soo jeedinaysaa in la isticmaalo farsamoyaqaan xirfad leh

- Isku dheelitir la'aanta cadaadiska mashiinka jeexjeexa ayaa sababa qalooca qaybta aan sinnayn, waxay soo jeedinaysaa in cadaadiska farsamaynta farsamada lagu ilaaliyo mid deggan.

B) Maaddada xudunta u ah oo laga soo fujiyay qaybta wejiga

-Marka la arko sababta oo ka baxaysa, fadlan eeg goynta miinshaarta ka hor inta aan la farsamayn.

-Marka aad wax fiirsato, ha ka gudbin khadka dhexe ee jeexjeexa, haddii kale saameynta ka dib foorarsiga ma buuxin doonto shuruudaha naqshadeynta.

Codsiga: